Our high-quality and long-lived Janssen F-Series cookie formers are specially designed for shaping individual small cookies up to large cake bases. We pursued three fundamental principles in the development of our multiple award-winning F-Series:

1) »Functionality« as a principle for avoiding unnecessary complexity while focusing on the performance required to facilitate our customers’ everyday production routines through a well thought-out interaction of technology and design under consideration of the applicable directives and standards.

2) »Ergonomics« The implementation of ergonomic requirements with respect to ease and simplicity of handling. Concretely, this means self-explanatory and intuitive operation allows a quick start with our cookie formers and assists you in your production processes, so that you can fully concentrate on the quality of your products.

3) »Hygiene« is the third fundamental principle of our Janssen cookie formers. All parts and components are extremely accessible and therefore very easy to clean and maintain. This establishes the ideal conditions for you to create flawless, high-quality products and to enjoy your machine for a long time to come.

Janssen cookie formers can be used to form individual cookies of different sizes and thicknesses with smooth or structured surfaces. Butter biscuits, fine tea cakes, almond biscuits, tartlets, but also gingerbread and Printen biscuits, as well as marzipan and sugar pastes can be formed efficiently with Janssen cookie formers.

Dough bands or lattice work of different dimensions and thicknesses with a smooth or structured surface can also be formed right into high cake trays. This means they offer an exceptionally versatile range of applications for small, medium-sized and large bakeries and confectioners.

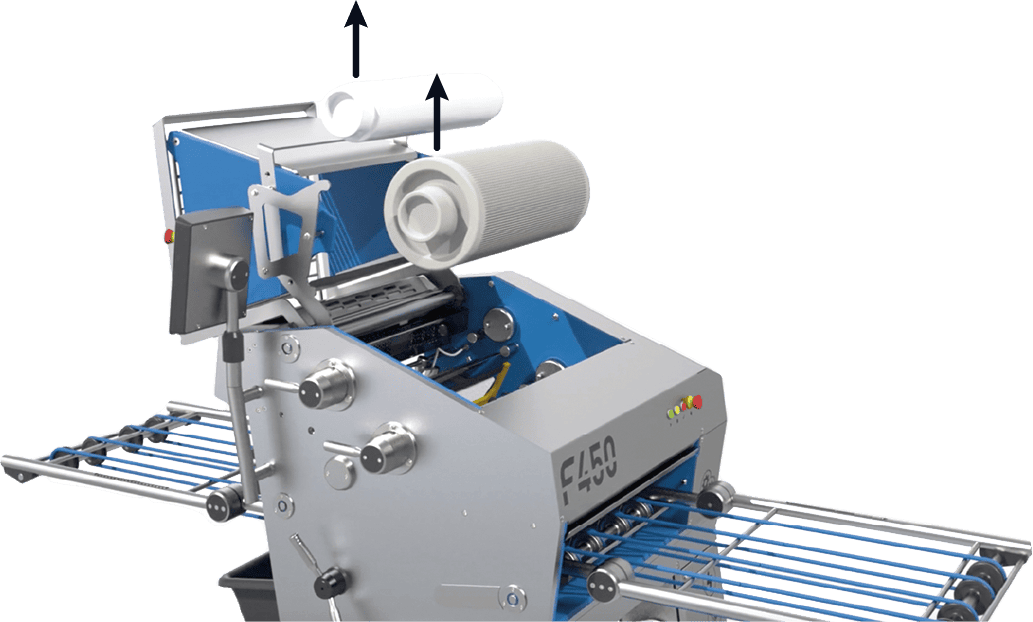

Pattern rollers

We offer our cookie formers in three different sizes with the ideal features to suit the baking sheet sizes you use as well as your intended output quantity.

You can use baking sheets of from 100 mm to 600 mm in width with flat or high edges. What’s more, the cookie formers can also be combined with band ovens.

Size comparisonQuick-release clamps that are very easy to use allow different pattern rollers for the production of different products to be installed in the machine in only seconds. Easy cleaning makes switching from one product to the next possible in no time.

... twist & release

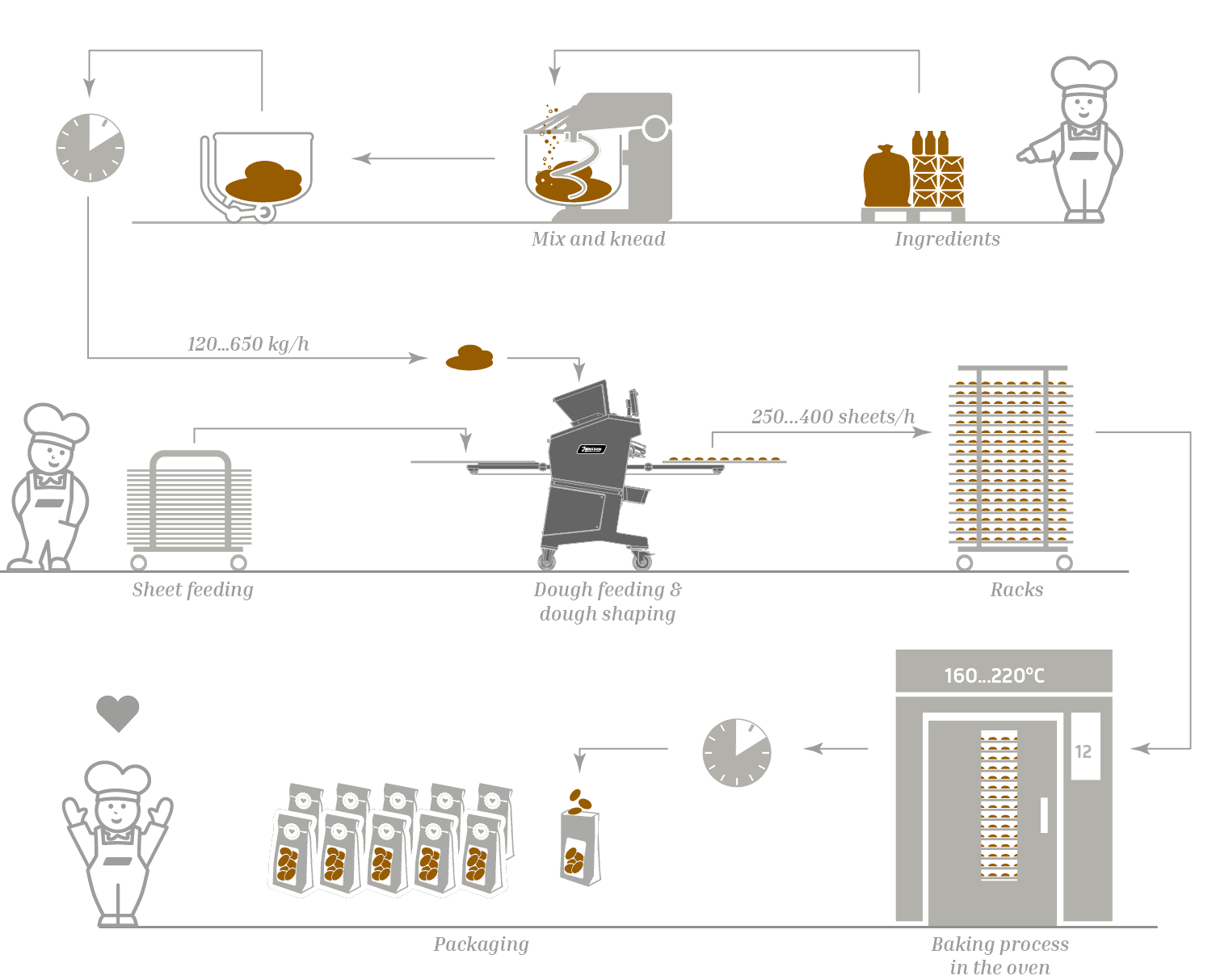

Our cookie formers in the F-Series work on the basis of a “cut-off principle.” Here, the dough put into the hopper in the form of crumbs, chunks or slabs is formed by the machine between the kneading roller and a pattern roller to produce the cookies and is then cut off at the base by a cutting blade. The individual cookies are placed on the conveyor belt and from there are deposited on the baking sheets which move by below the machine.

The dough is first prepared before the processing with our cookie formers, is then formed either directly afterwards or after a resting time, and is finally baked and portioned for sales.

Our cookie formers can be configured with helpful features, making them adaptable to your production needs.

Equipment