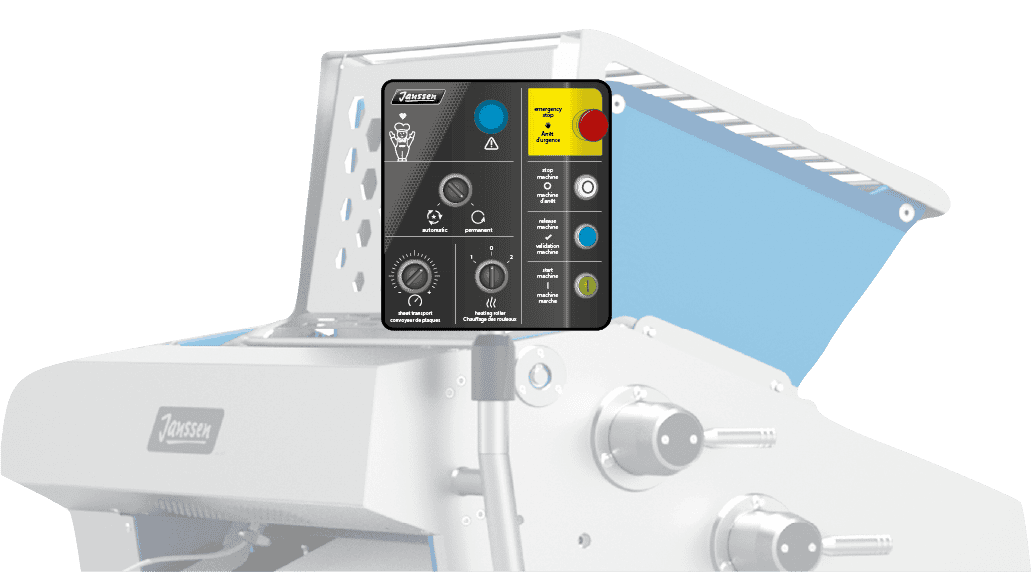

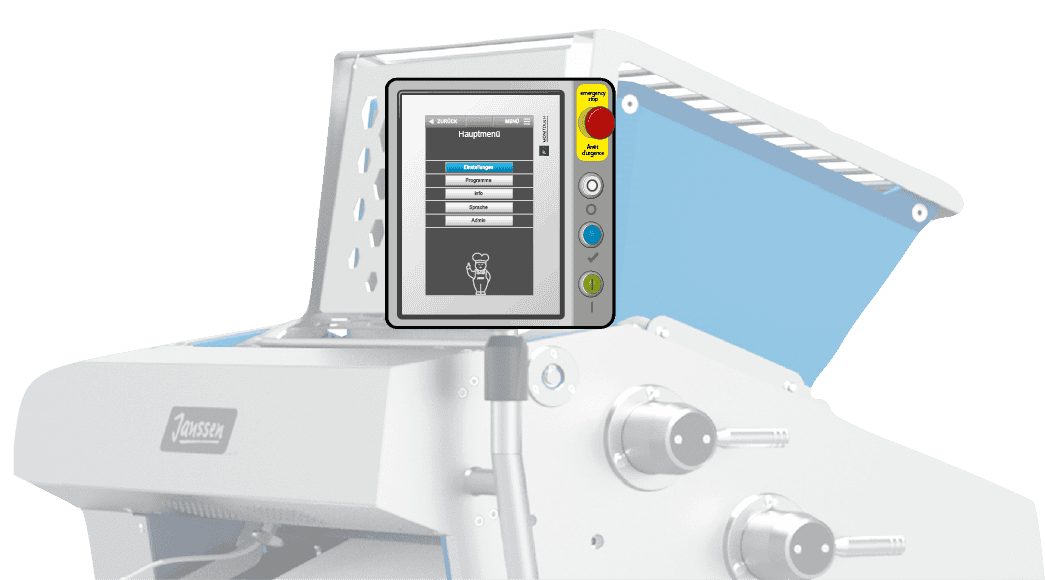

Depending on the focus of production, we offer two different controllers. Their range of functions results from the collective requirements of our customers as observed over recent years, and two versions have emerged.

The »Compact« controller is operated via a display with buttons and offers simple and convenient handling.

The »Performance« controller is operated via a touch display and offers comprehensive, easily programmable functions:

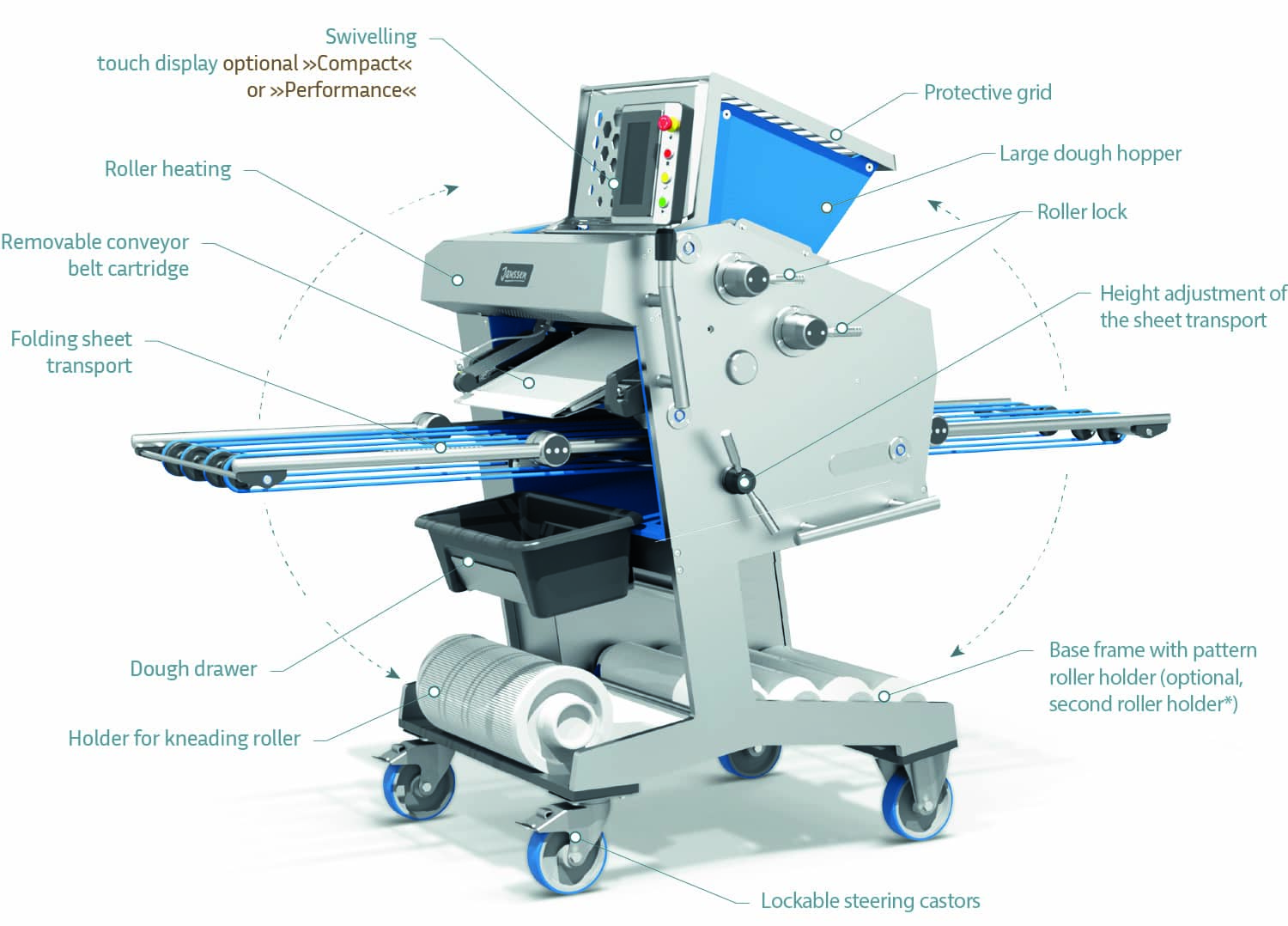

The roller holder in the base frame of the cookie former provides a safe and practical means of storage for your pattern rollers. The pattern rollers are protected in the storage area and can dry well after cleaning. As standard, 4 pattern rollers and one kneading roller can be stored. The cookie former can be equipped with a second roller holder for 4 additional pattern rollers as an option.

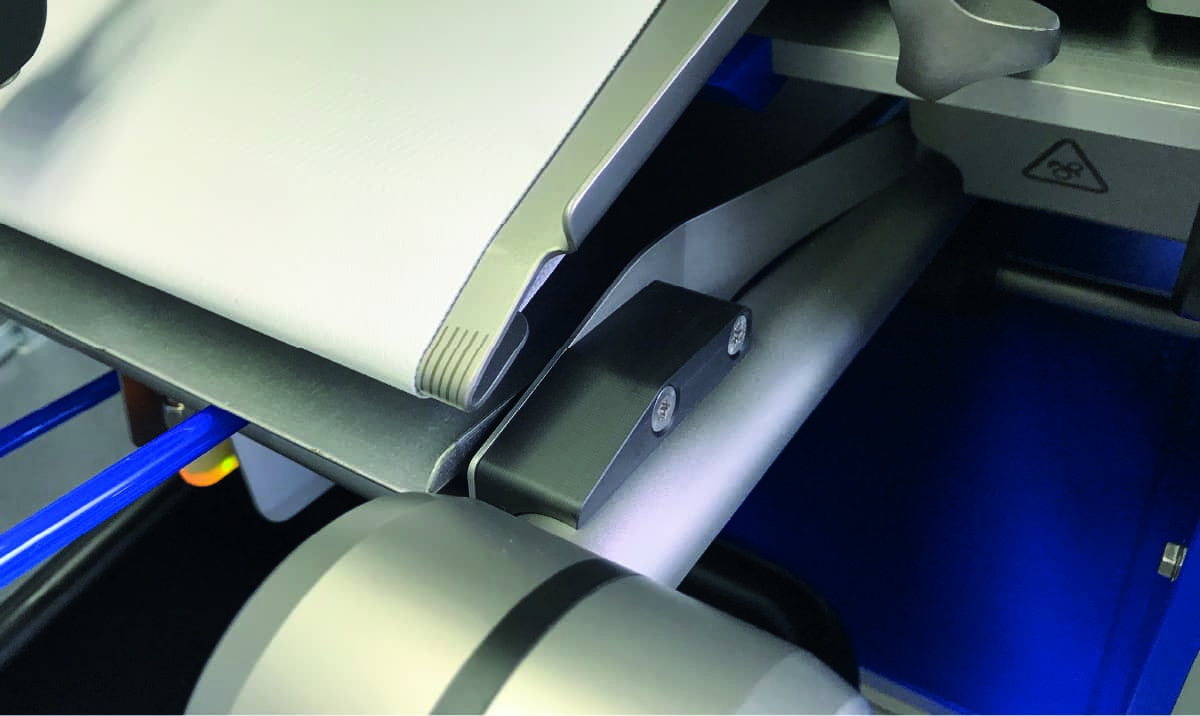

With individually adjustable dough dividers, you can shape dough bands of different widths for different cake trays using one and the same pattern roller. This allows you to load cake trays with a width of either 400 mm or 200 mm or even just 100 mm with one pattern roller.

To facilitate the use of baking sheets with a higher, circumferential edge, the cookie former can be equipped with a deposit ledge so that the cookies can be neatly placed on the baking sheet. The baking sheets with their edge can run through below the pivoting deposit ledge.

Small cookies (for example crescents) have a tendency to tilt and flip onto the wrong side while being formed and transferred to the baking sheets. The tilt protection bracket prevents the tilting of the cookies and can be adjusted very easily.

The use of cake trays with a width of 100 mm requires the additional use of sheet guide belts to ensure safe transport of the sheets and prevent them from tipping.

If you use baking sheets that have the maximum permissible sheet width of the machine and do not conform to standard dimensions, we recommend a front sheet guide to provide better guidance of the baking sheets through the machine. The sheet guide can be snapped in place easily on both sides and also removed for cleaning just as easily.

With adapters, you can use the rollers from your old K-Series cookie moulding machine in our new F-Series cookie formers. This means you can continue to use your old rollers when you buy a new cookie former. The prerequisite for this, of course, is a pattern roller that is undamaged and in good condition.

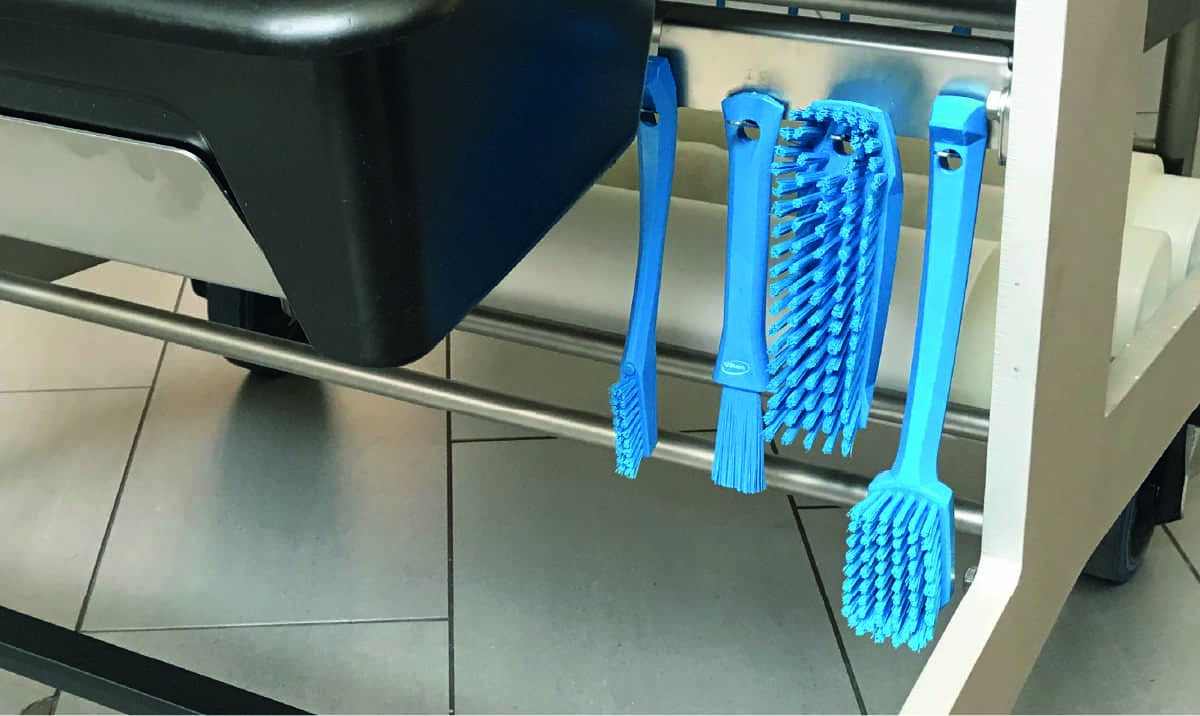

The brush holder directly on the machine means no time lost due to searching for the right cleaning utensils. The proper brushes are very well suited for cleaning the cookie former and are approved for use in the food industry.

Our cookie formers can also be combined with a band oven according to your needs. You can feed the loaded baking sheets next to each other over the entire width of the band oven or place the machine directly before the band oven. Depending on the dimensions of your band oven, the cookie former design can also be adapted and specially equipped. Get in touch with us!